Our patent pending directly Energized Silicon Carbide Crucible (ESCC™) is the most powerful and innovative ceramic heater ever made for oil concentrate vaporization. Cleaner, safer, better flavor and performance than anything, ever before. With proper care it can last years!

There is absolutely no comparison to anything else.

Other crucible or "insert" based atomizers use indirect heating also known as conductive heating, typically through a coil that is underneath the crucible. Sometimes the coil is embedded into a ceramic donut or disc, or even into the crucible itself. Indirectly heated crucible or insert atomizers are extremely inefficient at transferring heat to the crucible, regardless of material. This results in an extremely hot atomizer with very slow heat up time, at least 15 seconds with ceramic or quartz, usually longer. Indirect heating must use much more power to reach temp due to the inefficient and slow heat up time which significantly impacts battery life.

Additionally, indirectly heated crucible or insert atomizers must reach much higher temps at the coil than what the crucible temp is. This is to compensate for all the heat that is lost during the highly inefficient transfer of energy from the coil to the crucible. It is due to the flawed design of all indirectly heated crucibles. For a crucible temp around 500℉, the coil under it is reaching 600℉+, sometimes up to even 800℉ or more depending on the device and materials utilized. There is also solder or a tungsten slurry to connect nickel legs to the coil. Solder, tungsten slurry, and nickel legs are potent sources of metallic ions and for most users this creates a metallic taste in the vapor. It can even be harmful for some like those with nickel sensitivity or allergies. Most of the indirectly heated crucible atomizers on the market today have exposed solder or tungsten slurry to nickel legs next to high heat in the vapor/air path. Reaching temps over 600℉+ at the coil where nickel legs and solder or tungsten slurry is and exposed to your vapor/oil is not wise.

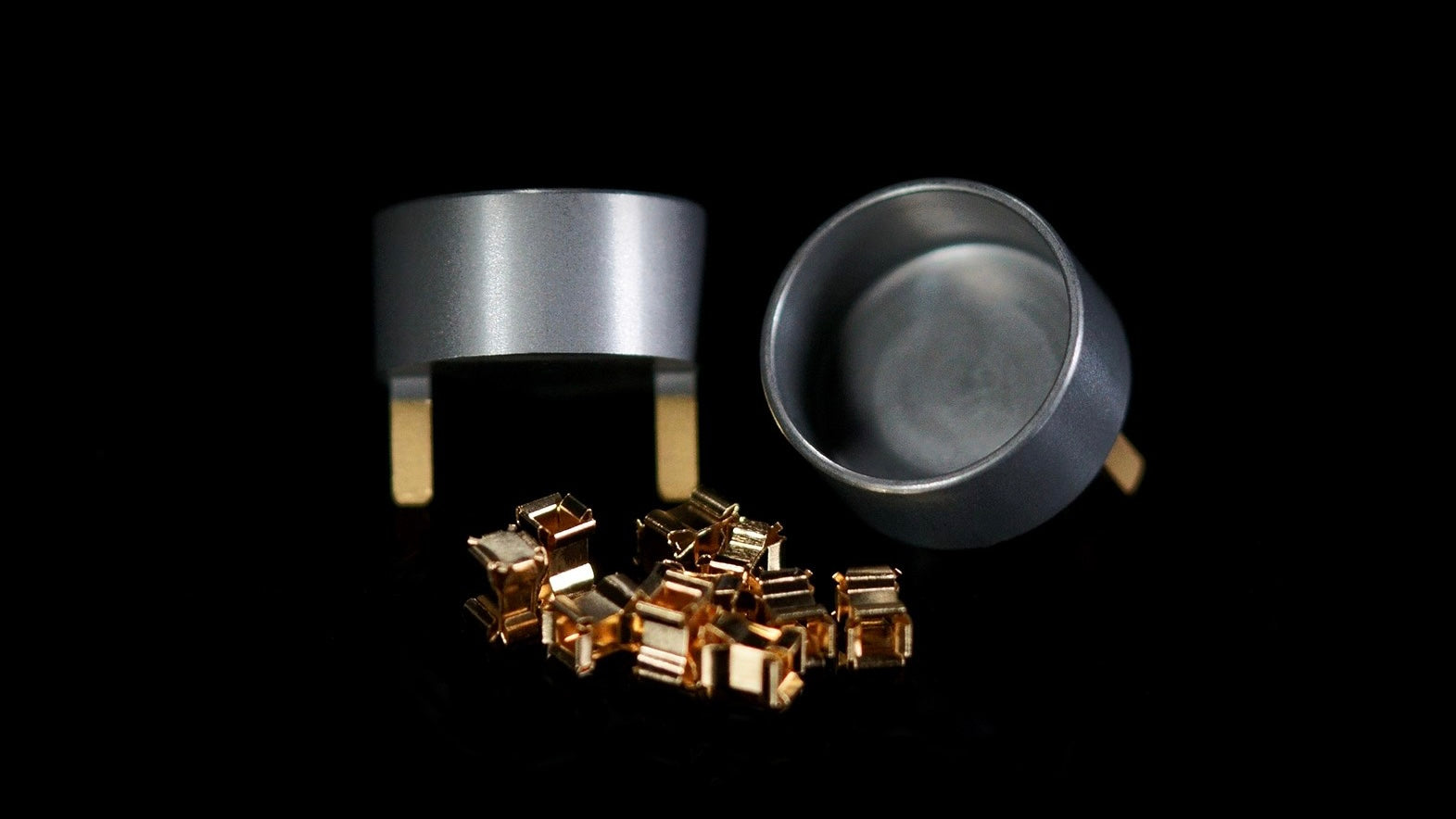

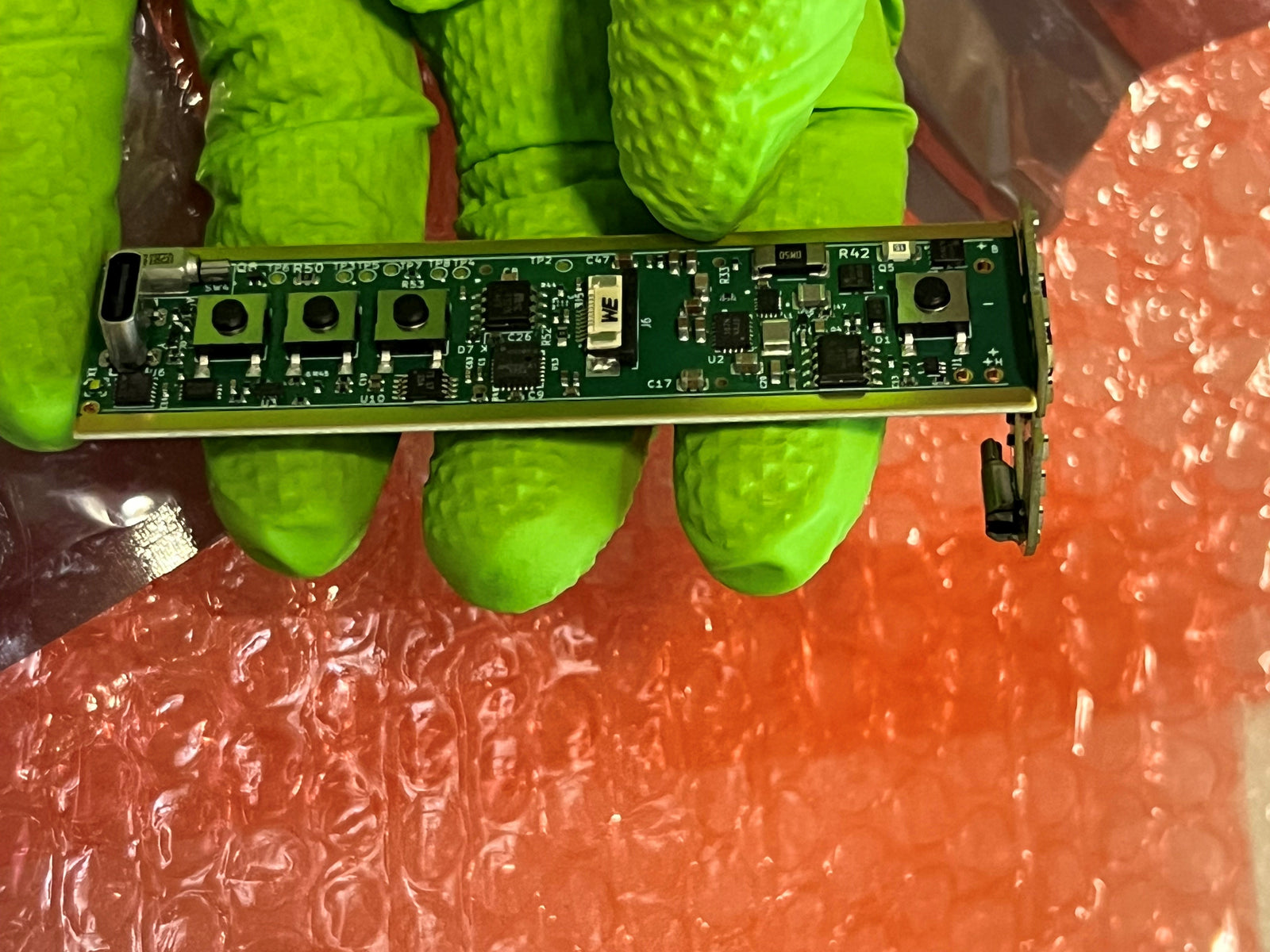

There has never been a truly "coil-less" crucible atomizer until now. The ESCC™ is the coil. By conducting electricity directly through the crucible, we can generate heat within the crucible material itself. This equals much faster/efficient heat up than anything a conductively heated atomizer is capable of, by a large margin. No solder or nickel legs, just some gold-plated stainless-steel clips to secure the crucible and complete the circuit! Since it is rebuildable, you can easily disassemble the entire M22 and see every single part yourself. You will find precision engineering and craftsmanship, with the highest quality materials we could source.

Indirectly heated crucibles cannot do real Temperature Control.

Temp control is a somewhat basic concept. Most electrically conductive materials have a TCR, or Temperature Coefficient of Resistance. This refers to the materials change in electrical resistance due to temperature. Materials with a large enough TCR, a big change in resistance with only a small change in temperature, can be used as a type of thermometer. The temperature of the “coil” can be determined by the change in electrical resistance.

Most companies use timed wattage as a very basic form of TC, and this is highly inaccurate. Some refer to Temp Control as measuring the heat coming from the heating coil or donut under the crucible and advertise this as TC, which is false advertising. This can at best only prevent overheat but does not actually control or hold the temperature with changing variables like the type of material, airflow etc. They should call it overheat protection, which is the second to lowest form of "TC", timed wattage being the lowest. This is not real or actual temperature control.

When airflow is drawn into the crucible, heat is immediately taken away from the crucible. Depending on what material the crucible is made of, the amount of heat loss can vary. The viscosity (type of oil), amount of oil, and when you load your oil during the process will also change the temperature of the crucible. Indirectly heated crucible atomizers will not and cannot immediately detect or react to these changes as there is no direct impact or change to the resistance of the coil that is not in direct contact with these variables. Therefore, the coil will not change in resistance right away and there will be a relatively long delay between what is happening in the crucible vs the coil. It is like having cruise control on a weak car that does not respond to a hill immediately, as a result you slow down up the hill and then accelerate back to speed once you are over the hill.

There are different methods companies use to deal with this, but they do not actually solve the flaws with indirect heating. The main approach used is to ramp up to higher temps initially such as 500-600℉+ to do what the ESCC can do at an actual 400-470℉. It is like setting the cruise control on the car from my previous analogy well over the speed limit before the hill so that when you reach the hill your car slows down to be at the intended speed.

Due to our crucible being directly powered or 'energized' with sufficient TCR, its change in electrical resistance can be monitored directly which allows for unprecedented TC accuracy and performance from a crucible. It is what is known as a thermistor, basically the crucible is its own thermometer.

With the ESCC™ more of the energy is utilized when and where you want it with near instant reaction time and reaching up to 600℉ within 5 seconds! Adjusting the wattage output will speed heating time up more or slow it down. Do not be fooled by other companies claims to have the best flavor, performance, or the most efficient design, or “special materials" that are usually way overpriced, they all greatly under-perform when compared to the ESCC™. Nothing comes close to the energy efficiency, performance, or flavor of the ESCC™ and Molecule22, nor will anything else come close, unless it is us making an even better ESCC™😉

Molecule22 w/ ESCC™

- Extremely efficient, nothing else comes anywhere close to the thermal or electrical efficiency of the ESCC™, which results in long battery life and quick dabs on demand.

- Does not have a coil, the crucible is the hottest part in the system. There is no overheating coil with solder to nickel legs under or in the crucible. No solder or glue anywhere in the atomizer, as a rebuildable atomizer everything is assembled mechanically. Only stainless steel, 24k gold plating, glass, zirconia and silicon carbide ceramics in the vapor path.

- Amazing pure flavor and unrivaled efficacy per drop unlike anything else.

- The ESCC™ is the only crucible tech capable of real and actual temp control that will actually respond to the oil amount or type of oil loaded to maintain and hold real temps and react nearly instantly to changes in variables like airflow or environmental factors. Other companies claims to have TC in a crucible is a flat out lie.

All other crucible/insert atomizers

- Extremely inefficient, take a very long time to heat up while using a lot of power to reach temp, which is bad for portability and battery life.

- Must reach higher temps at the coil than what the crucible is. The solder, or tungsten slurry to nickel legs reaches high temps and adds a metallic flavor for most people. Nickel can be harmful to some.

- Cannot do actual and real Temp Control! It is a scientific fact.

- Bad flavor, scorched terps.

Welcome to the future of dabbing.

Kyle B

March 06, 2023

So you figured out dabbing… very good job and an extremely, extremely impressive design!

Now I’d love for you to conquer dry herb. Most herb vapes have so many compromises, variables, and complex problems that I believe you would be able to solve. Ball vapes are the most efficient (extraction wise) and are an easily adjustable way to vape but require an outlet, temperature controlled box, and need to be left on for optimal results. Most devices use inefficient heating systems, requiring long heat up times or give inefficient extraction of the herb. Honestly the best I can do with my Qaroma shop ball vapes is a 40 second extraction for .15-.25g of flower at best (two to three 10-second hits)

It seems that no matter what method or technique I try, herb is a stubborn material to extract oil out of and can be easily under or over extracted.

If you could figure out a bowl design or a different crucible design; that would make a complete 4 in 1 system, I’d order almost immediately