Boiling points, atmospheric pressure, and temperature: what they mean for vaporization.

The idea of a “perfect session” can look like different things for different people - it all comes down to personal preference. Regardless of what your perfect session looks like, you should be able to achieve it every time easily and consistently. However, changes in environmental variables like atmospheric pressure and temperature make this easier said than done. Achieving this level of repeatability requires hardware and software capable of tracking all these different variables and adjusting accordingly in real time. Let us dive into the science now!

When vaporizing concentrates different variables play a key role in desirable, consistent, and predictable vapor production. The boiling point of the material we are vaporizing is the most important variable. Usually, this material consists of different compounds that have their own independent boiling points. (If you haven’t read our blog post about “Cold start and low temp” I recommend doing so as we dive a little deeper into the science of that topic there.) To vaporize the material, we need to build vapor pressure by heating it until the vapor pressure matches the atmospheric pressure. This equilibrium is the material’s boiling point. Both changes in atmospheric pressure and naturally occurring variations in the material will influence its boiling point - and by extension - the best temperatures to use for vaporization.

What is atmospheric pressure and why does it change? Atmospheric pressure is the weight of all the air above us and our elevation is the major reason atmospheric pressure changes, but not the only reason. The higher up we go, the less air there is in the remaining atmosphere above us, therefore less air weight or pressure. The opposite is true at lower elevations - more air weight above means more pressure below. Atmospheric pressure also experiences slight changes at any given location and watching these changes in pressure plays a key role in predicting the weather. When you hear weather forecasters talking about pressure systems it is because these pressure fluctuations result in changing weather conditions. This means that various locations require different temperatures and heating curves to achieve consistent and predictable vapor production.

Some people might think a vacuum is created in the device during use and that atmospheric pressure would not matter. This is not correct though. Firstly, a vacuum is not created during use. In scientific terms, a vacuum is defined as “space in which there is no matter or in which the pressure is so low that any particles in the space do not affect any processes being carried on there.” When using a vaporizer, air is being drawn into and through the device by the lower pressure that we create when filling our lungs for a puff. Therefore, the vaporization chamber is not devoid of matter (air) and its pressure is not significantly lower than atmospheric pressure, even if we inhale as quickly as possible (which is not how people take a puff.) A vacuum cleaner works similarly and despite the name is also not creating a true vacuum. We could say it creates a “partial vacuum,” but it is more accurately just creating lower pressure.

Secondly, atmospheric pressure is going to affect the amount of pressure that can be created. From our previous example, atmospheric pressure impacts the performance of a vacuum cleaner for the same reason. “Because it is really the atmosphere that is doing the pushing...”. When taking a puff, we create an area of lower pressure in the device which causes the higher pressure of the surrounding atmosphere to push air into the device. At its core, the characteristics of this air flow are a matter of fluid dynamics and Bernoulli’s theorem. When we restrict airflow into the device and create lower pressure, we are still drawing air in from the atmosphere around us. The atmospheric pressure pushes the gases through the device towards the lower pressure area we are creating in our lungs. By restricting air inlet size, we speed up air flow as the atmospheric pressure pushes through the smaller opening faster, creating a jet of air. Directing this jet of air at the material mixes the three key elements of vaporization (heat, oil, and air) together more effectively and aids in defeating van der Waals forces, breaking molecular bonds and thereby increasing vaporization. Changes to atmospheric pressure impact vaporization performance in a measurable and predictable way.

Atmospheric temperature is another important variable. Combined with atmospheric pressure, the temperature of the air around you that is entering the system also has an impact on vaporization performance. The temperature of the environment will impact things like battery performance as well.

In conclusion, adjusting for the type of material to be vaporized, atmospheric pressure, and temperature is important for consistent and predictable vaporization performance in any device that draws air in from the atmosphere.

Coming up in the next blog post: “Molecule Control Tower - What technology sets it apart from traditional batteries and electronics used for other vaporizers?”

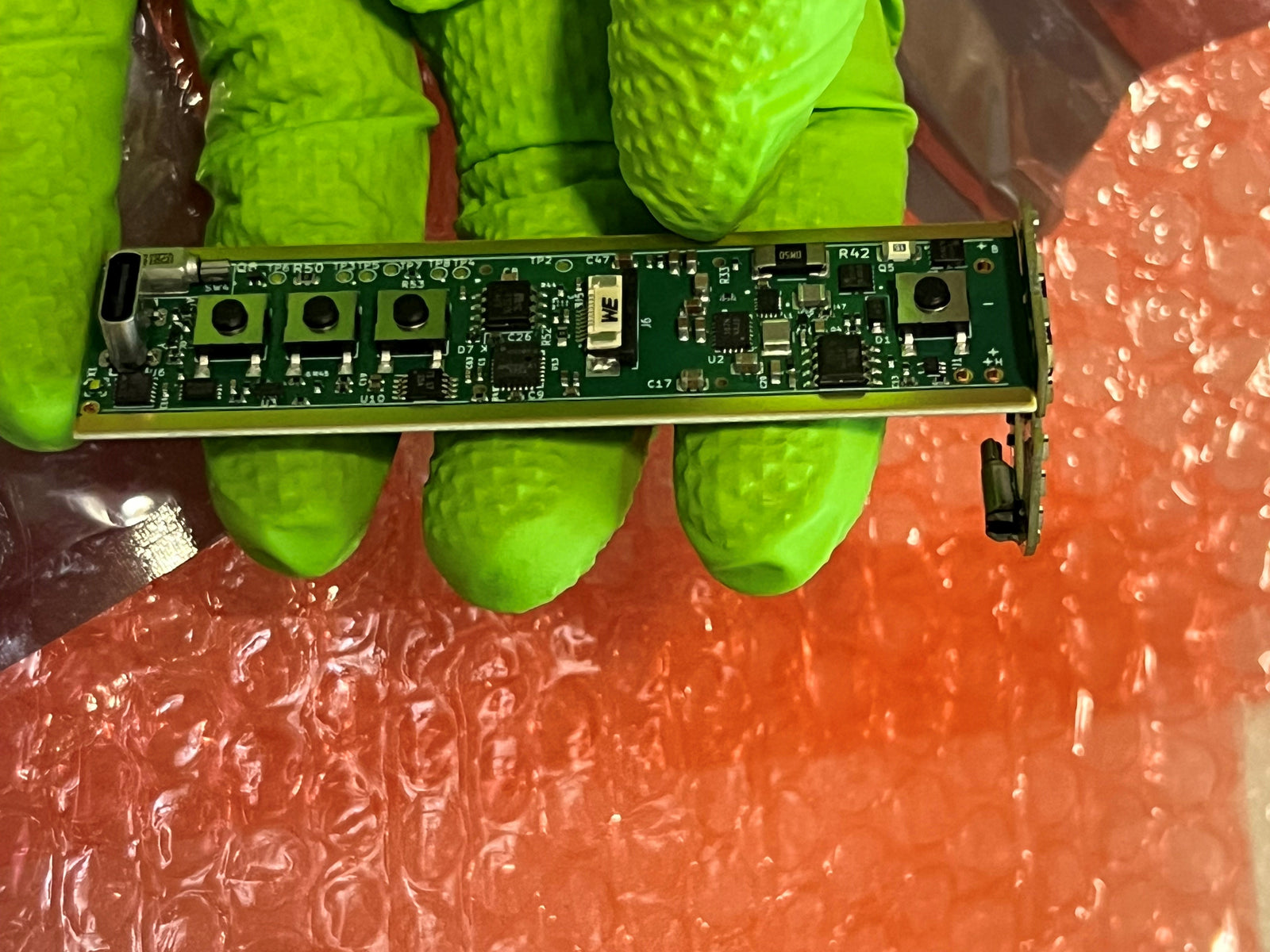

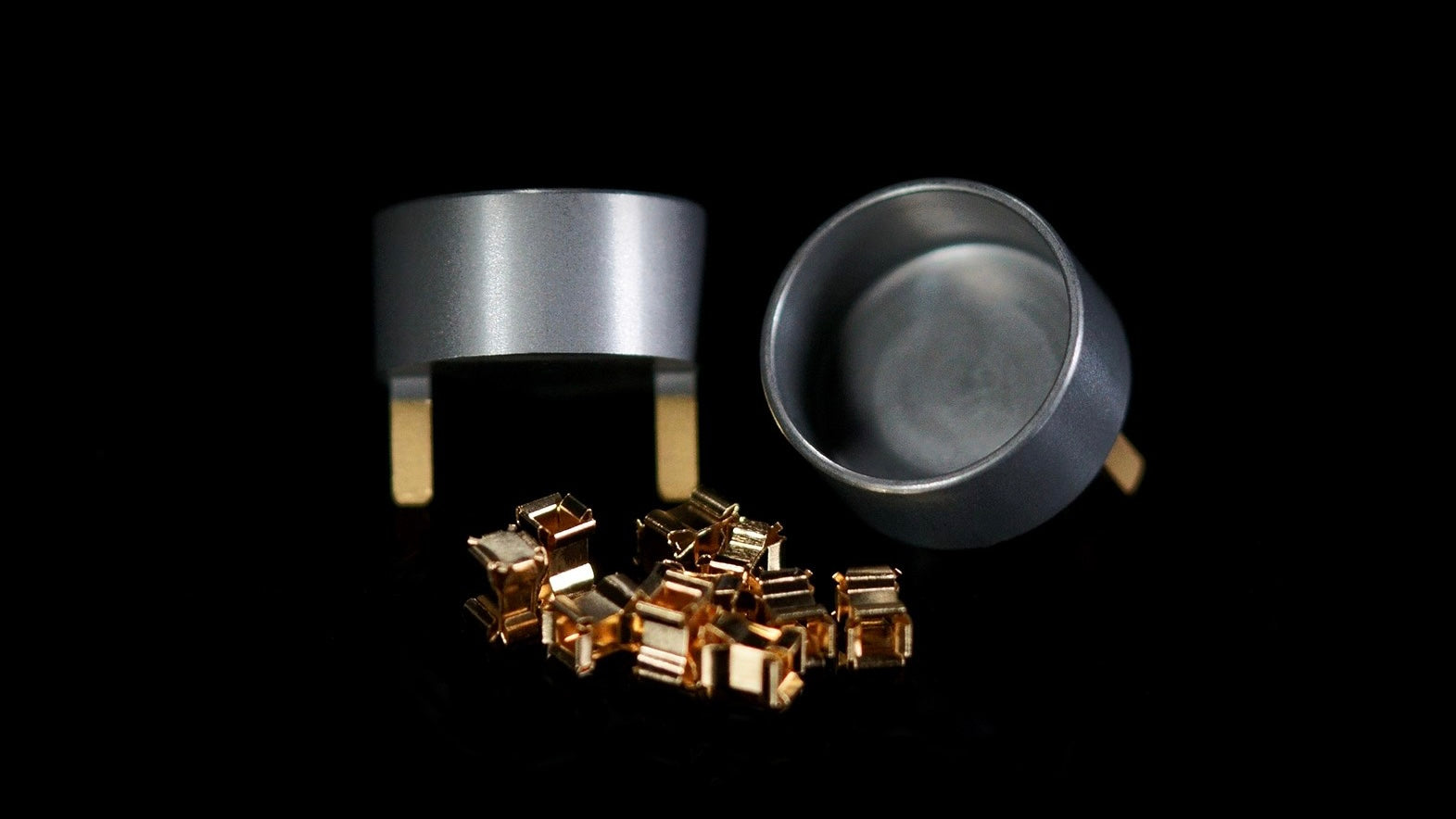

No concentrate vaporizer has ever been built to take atmospheric pressure into consideration until now. The Molecule Control Tower features a barometric pressure sensor, using this it adjusts for the atmospheric pressure around you. The Molecule22 system is not only the most versatile and high-performance device for concentrate vaporization, but also the most scientifically advanced and capable. It features the one-of-a-kind patent pending ESCC (Energized Silicon Carbide Crucible) - the first directly powered ceramic crucible ever made. This means no heating coil is used anywhere in the device. (Learn more about this groundbreaking tech in our blog post “Why the ESCC is superior” if you haven’t already.) Due to the unprecedented temperature control accuracy that only our crucible is capable of, nothing else compares to our technology - not even close!

*This post was reviewed for technical accuracy by two other members of AVS who are both doctors.

Dr. Daniel McShan - VP of Engineering – PhD in Computational Bioscience. He is a part owner of AVS and was previously working in aerospace programming rockets and rovers.

Dr. K – initial for privacy as he is not ready to publicly disclose his personal identity – MD, MPH. He is a renowned cancer surgeon working full time at a prestigious research medical facility. He collaborates with us part time and is also a part owner of AVS.

This post was also edited based on feedback from a group of our customers on discord for readability.

Encyclopedia Britannica definitions:

Boiling Point - Vapor Pressure - Vaporization - Atmospheric Pressure - Bernoulli's theorem - Vacuum - van der Waals forces

Cody Davis_Santa Cruz

December 20, 2021

Very interesting read. I’m starting to understand why my escc performance is so amazing, the future is now.lol